Isebenzisa i-titanium dioxide powder kwizicelo ezahlukeneyo

Ukwazisa ipremiyamu yethuI-titanium dioxide ye-Masterbatches, isohlwayo esisemgangathweni, esongeneyo esenzelwe ngokukodwa ukuphucula amandla kunye nobumhlophe beemveliso zeplastiki. Iimveliso zethu zibonelela ngeepropathi ezizodwa, kubandakanya nokufunxa kweoyile ephantsi, ukuhambelana ngokupheleleyo kunye nokubuya kweplastiki kunye nokukhawuleza, ukusasazeka ngokupheleleyo.

I-tioxide yethu ye-tioxide ye-stalbatches ilungele iintlobo ezahlukeneyo zezicelo, kuquka nemveliso ye-polyproplene. Ngomgangatho ophezulu kunye nokusebenza, sisisombululo esifanelekileyo sokufezekisa umbala ofunekayo kunye ne-opacity yeemveliso zeplastiki.

Iimveliso zethu ziyafumaneka kwiFowuni loMgubo oLungileyo, ibetha ukuba zilula ukuba zibandakanye kwifomu ye-Masterbatch. Ubungakanani bayo obuphakamileyo kunye nobungakanani beperpecles

Esona sibonelelo siphambili sethuI-titanium dioxideKwi-stasterbatches yindawo yalo yeoyile ephantsi, okuthetha ukuba ingasetyenziswa kwifomu ngaphandle kokusebenzisa intsebenzo yeplastiki. Oku kugcina iindleko kwaye kunyuswe ukusebenza ngempumelelo kwenkqubo yemveliso.

Ukongeza, iTikogi ye-tioxide yethu ye-stasterbatches inoluhlu olubanzi lweendawo zokubuya ngeplastiki, ukuqinisekisa ukuba ingabandakanywa ngokungagungqiyo kubandakanywe kwifomu okanye umgangatho. Ukuhambelana kwawo kunye nokubuya kwawo kwenza ukuba kuthathe ukhetho lwabavelisi abajonge ukufezekisa umbala oguqukayo kunye ne-opacity kwiimveliso zeplastiki.

Ukongeza, iimveliso zethu zaziwa ngokusasaza kwabo ngokukhawuleza kwaye zigqibe ukudibanisa okulula nokuyisebenzayo kunye nezinye izithako ze-starbatch. Oku kuqinisekisa ukuba i-titanium diokside isasazwe ngokulinganayo kwi-matrix yeplastiki, ikhokelela kumbala ofanayo kunye ne-opacity kwimveliso yokugqibela.

Nokuba uvelisa i-polyproplene stasterbatches okanye ezinye iimveliso zeplastiki, iTitanium yethu ye-tioxide yindlela efanelekileyo yokufezekisa ubumhlophe obufunekayo kunye nokungasebenzi. Ukusebenza kwayo okhethekileyo, ukutya okuqinisekileyo kunye nokuncipha kokusetyenziswa kwenza ukongezwa okuxabisekileyo kulo naluphi na umthetho obalulekileyo.

Kwisishwankathelo, iTitanium yethu ye-Dioxide ye-Masterbatch sisiseko esiphezulu sendlela yokusebenza, egqwesileyo kunye nokusetyenziswa ngokulula. Ngomsebenzi wayo ophantsi weoyile, i-powder yomgubo ocolekileyo kunye nokusasazeka ngokukhawuleza, kufanelekile ukufezekisa umbala oguqukayo kunye ne-opacity kwimveliso yeplastiki. Khetha iTikogide yethu ye-tioxide ye-Masterbatches ukuphucula umgangatho kunye nokusebenza kwenkqubo yakho yeplastiki.

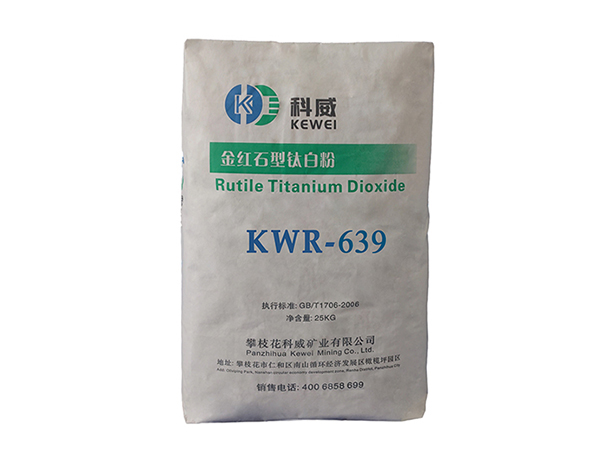

Iphakheji

Ipharamitha esisiseko

| Igama leekhemikhali | I-titanium dioxide (i-tio2) |

| I-HAYS No. | 13463-67-7 |

| I-einecs hayi. | 236-675-5 |

| ISO591-1: 2000 | R2 |

| I-ASTM D476-84 | I-III, iv |

I-Lonketor yobugcisa

| I-TIO2,% | I-98.0 |

| I-volits nge-105 ℃,% | I-0.4 |

| I-inorganic | I-alumina |

| Indalo | unayo |

| Umcimbi * Ukuxinana kwe-Bulk | 1.1G / CM3 |

| Ukufunxa ubuninzi obuthile | cm3 r1 |

| Ukufunxa kweoyile, g / 100g | 15 |

| Inombolo yesalathiso yesalathiso | I-pigment 6 |